Led Tube Lights: Picking the Right LED Tube for Your Application

For the billions of square feet of commercial real estate that have not undergone a lighting upgrade within the last several years, LED tube lights are the quickest and easiest way to reduce energy consumption and lower monthly utility bills. LED tubes have come a long way since they were first released, with improvements in light output, color rendering, and lifespan coming at each iteration. Through each generation, manufacturers have been able to reduce the cost and improve their process. For you, the consumer, this means that high quality LED tube lights are quickly approaching the low cost of premium standard fluorescent T8 tubes. In this article, we'll cover what you need to know to pick the right LED tube light for your application.

What Are LED Tube Lights?

LED tube lights are the lighting industry's answer for the need for more efficient versions of the trillions of linear fluorescent lamps that are currently in use throughout the world. With legislation increasing the efficiency requirements for these linear fluorescent lamps and the phasing out of many popular models, the LED tube light stands as the easiest replacement option for those older fluorescent lamps like the 4 and 8 foot long T12 lamps and 4 foot long T8 lamps. In the most basic terms, an LED tube light is an LED light bulb that is made to fit into existing fluorescent lamp fixtures, The bulb is the same length as the traditional fluorescent lamps and has the same type of terminals on the ends. That's about all these lamps have in common with the traditional fluorescent lamps, however. The body of the lamp is typically made from a combination of aluminum, plastic or polycarbonate materials. The light comes from a series of LEDs that are installed onto circuit board strips inside of the tube. These lights also have quite a bit of circuitry inside to drive the LED chips with whatever type of input power they're receiving. Depending on the type of LED tube light, the power that drives them can vary quite a bit.Ballast-Bypass LED Tube Lights

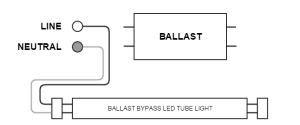

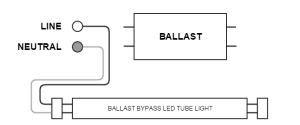

[caption id="attachment_745" align="alignright" width="300"] Typical wiring diagram for ballast-bypass LED tube lights.[/caption]

Typical wiring diagram for ballast-bypass LED tube lights.[/caption]

The first LED tube lights that were introduced were ballast bypass lamps. These had simpler drive circuits inside that required line voltage to be supplied to the terminals in order to work. Early versions were available with either single-ended or double-ended power requirements, but the industry has migrated to single ended power due to safety concerns and standardization.

In order for these lamps to operate, the ballast has to be bypassed and line voltage has to be supplied directly to the lamp terminals. For single-ended lamps, this means that shunted lamp holders will not work. Lamp holders have to be able to supply different voltages to each pin on the end of the lamp.

[product ids="3369,2328,3284,3285"]

Typical wiring diagram for ballast-bypass LED tube lights.[/caption]

Typical wiring diagram for ballast-bypass LED tube lights.[/caption]

Ballast-Compatible LED Tube Lights

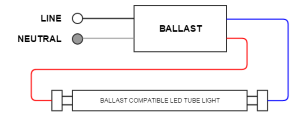

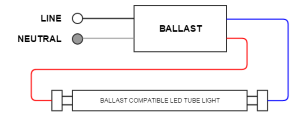

[caption id="attachment_746" align="alignright" width="300"] Typical wiring diagram for ballast-compatible LED tube lights.[/caption]

Typical wiring diagram for ballast-compatible LED tube lights.[/caption]

Ballast-compatible tubes are made to work with the same input power that drive fluorescent lamps. This means that the user does not have to remove the existing ballast in order to install this type of tube light. While the ease of installation is a clear benefit, the ballast will still be consuming some power and will remain as a maintenance concern going forward. This style of LED tube light is also called a Direct Replacement LED Tube because it can directly replace the existing T8 lamps in modern fluorescent fixtures. Care should be taken to ensure that the lamps are compatible with the existing ballasts. Many direct replacement lamps are intended for use with instant-start electronic ballasts, but lamps are also available that can work with dimming and emergency ballasts as well.

[product ids="3368,3376,3359"]

Typical wiring diagram for ballast-compatible LED tube lights.[/caption]

Typical wiring diagram for ballast-compatible LED tube lights.[/caption]

LED Tube Lights vs. Fluorescents

While fluorescent technology is certainly more mature, the merits of LED tube lights as replacement for inefficient T12 and T8 lamps are many. The table below attempts to summarize the factors that should be considered when making this decision.| Metric | T8 Fluorescent | LED Tube Lights |

|---|---|---|

| Power Consumption | 28W-32W for 4' T8 | 15W-22W for 4' T8 LED Tube |

| Lifespan | 20,000-30,000 hours typical. 50,000 hours under certain conditions for extended life versions at a premium. | 50,000+ hours typical. |

| Lumen Output | 2900-3200 omni-directional. Requires reflectors to direct light to work surface. | 1900-2600 directional light output. Light is not lost in the fixture or behind the lamps. |

| Efficiency | 85 lm/W typical when new with significant degradation excluding fixture efficiency. | 100+ lm/W typical |

| Initial Cost | Low. $2.75 - $10.00 per lamp. | Higher but dropping fast. $7.99 - $25.00 per tube. |

| Operating Cost for 1 Year | $35.74 for 32W lamp and HBF electronic ballast running 24/7 for 1 year. | $18.92 for 18W ballast bypass running 24/7 for 1 year. |

| CRI | 80+ typical with higher CRI available at steep price increase. | 80+ typical and improving quickly. |

| Controlability | Frequent on-off cycles reduce life. Can be dimmed, but at high cost. | Solid state allows for fast on-off switching with no effect on lifespan. Can be dimmed at minimal to no added cost. |

| Effect of Temperature | Low temperatures reduce light output. | Operates at low temperature with no effect on light output. |

| Material | Glass tube requires shatter proof coating or guards for use in food safe facilities. Coating reduces lamp life and increases cost significantly. | Does not contain glass. Can be used in food prep facilities as is. |

| Environmental | Contains mercury and other hazardous chemicals. Requires proper disposal. | Does not contain hazardous chemicals. |

Which One Is Right for Your Application?

With all of the different marketing names attached to the various kinds of LED tube lights on the market, it's easy to get overwhelmed. Picking the right type doesn't have to be difficult, however. The decision should come down to what the main objective for the change is. If the objective is to reduced energy and minimize maintenance costs, we would recommend bypassing the ballasts in the existing fixtures and using LED tubes that have internal drivers. This removes another potential failure point in the fixture and reduces the energy consumption for the fixture. Typical applications that may chose this route include:- Large commercial office buildings

- Schools

- Churches

- Manufacturing facilities

- Warehouses

- Private homes and residential

- Individual small business offices

- Shops and retail facilities

Need Additional Help?

If after reading this, you find yourself needing more help picking the right LED tube light for your application, we're here to help. RelightDepot has the expertise to guide you through the whole process. Contact us at [email protected] or call 888-548-6387 and speak to a lighting expert right now.

October 20, 2015